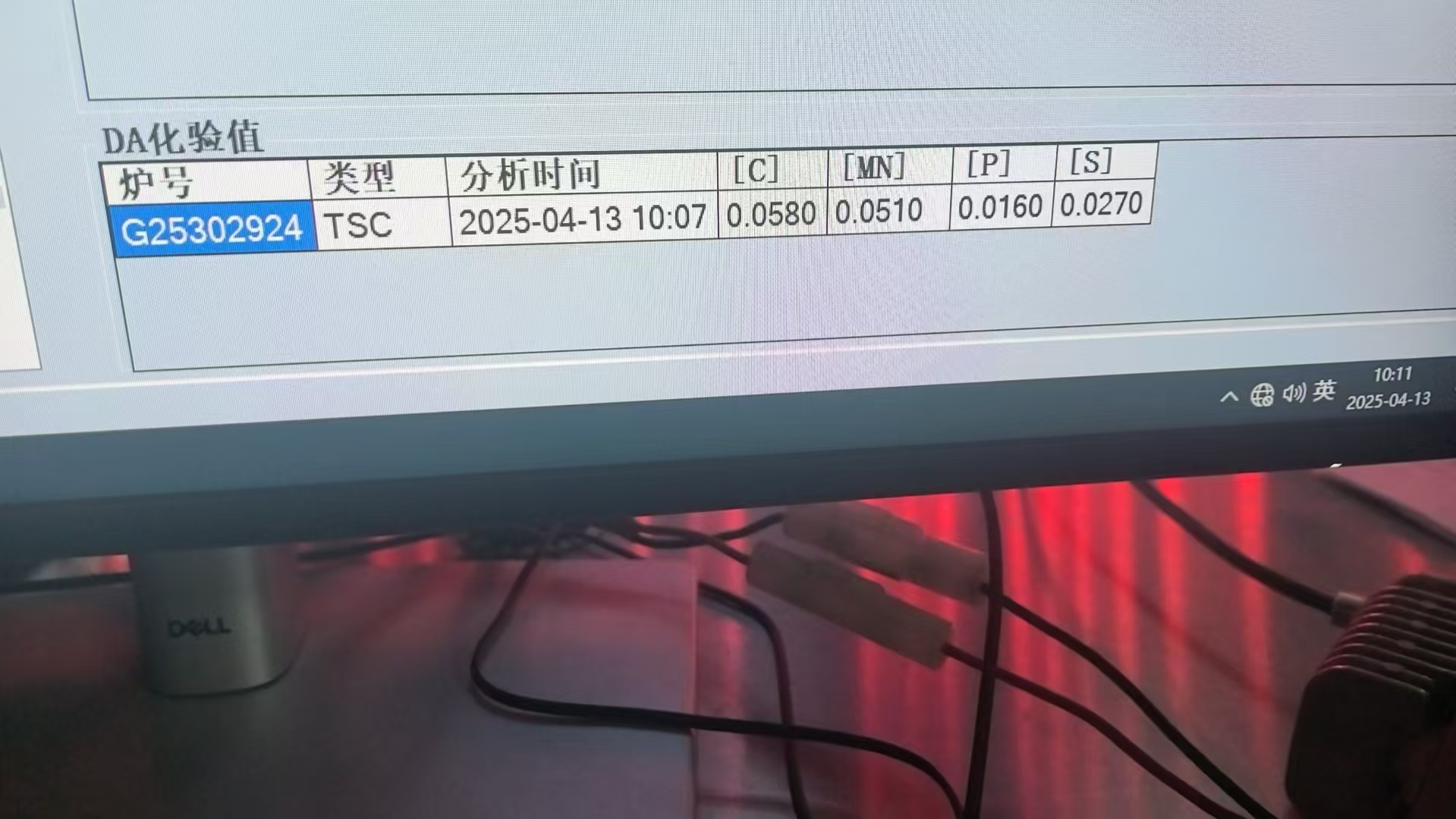

April 13, 2025, 10:10 AM — The successful first measurement performed by the sublance systems at Fengnan Zongheng Iron & Steel Co., Ltd. marks the official commissioning of the complete sublance systems delivered by our company. This milestone event signifies the full operational deployment of the integrated solution, demonstrating seamless coordination between advanced detection technologies and process control logic under actual production conditions.

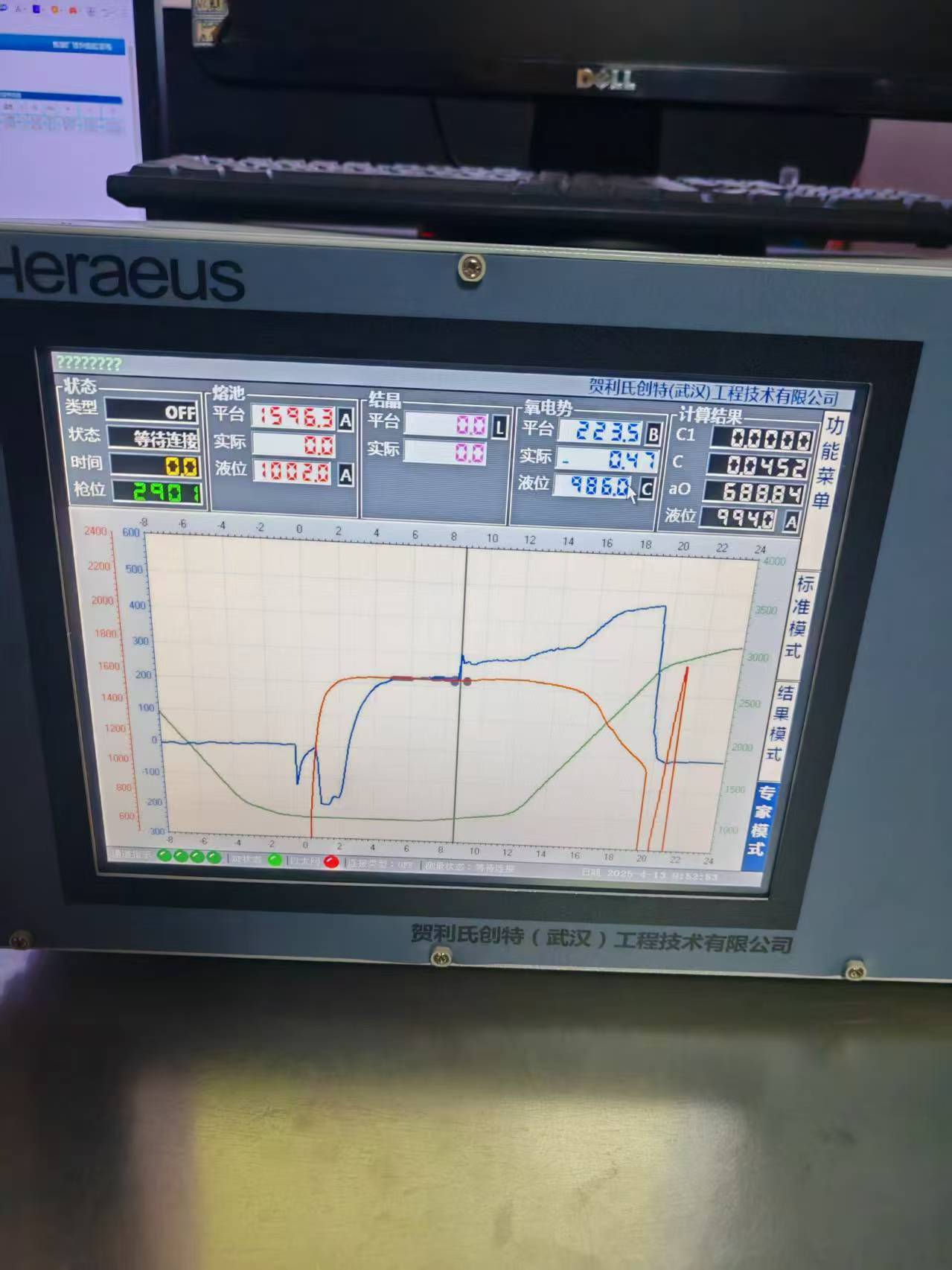

Model blowing tracking

Model dynamic calculation

MAS-T400 Sublance Instrument

Fengnan Zongheng Iron & Steel Co., Ltd. has successfully commissioned its upgraded sublance systems. Building upon the original configuration, our team implemented groundbreaking innovations by integrating four advanced subsystems: the Audio-Based Slag Formation System for real-time slag monitoring, the Flame Analysis System for combustion diagnostics, the Flue Gas Analysis System for emission tracking, and the DA rapid analyzer for instantaneous composition measurement.

Audio-Based Slag Formation System utilizes sonar technology to capture noise within converter flues. Through electronic processing, it detects and analyzes acoustic signals generated during the oxygen-blown slag formation process, continuously monitoring slag condition changes.

This system is a comprehensive solution for flame monitoring and slag dumping image acquisition at the converter front. By installing industrial cameras to capture real-time flame images at the converter mouth, it enables remote "flame observation" operations.

The flue gas analysis system continuously monitors gas concentrations (including CO, CO₂, and O₂) in process gases generated during converter steelmaking.

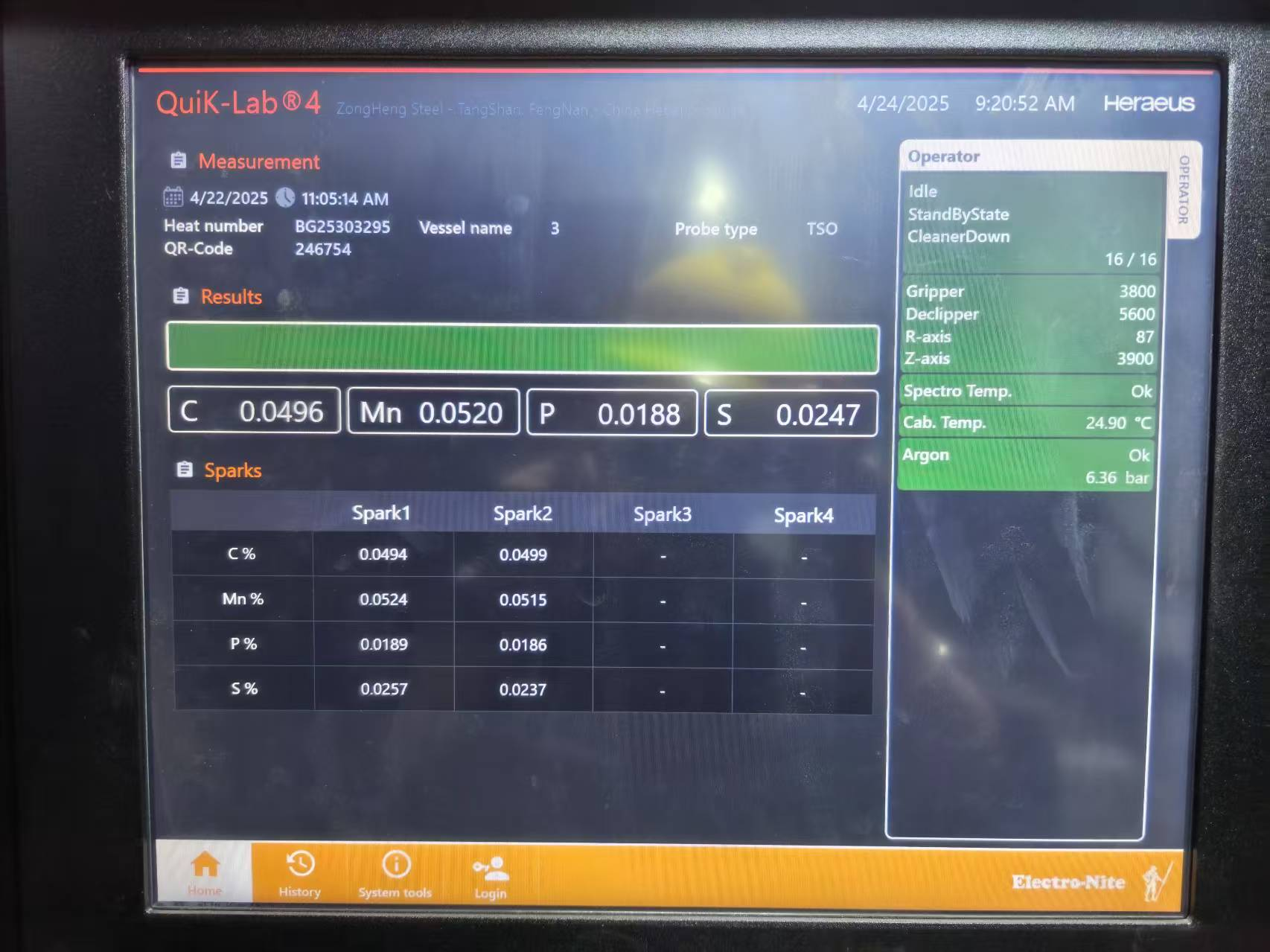

The DA rapid analyzer streamlines steel composition testing through its dedicated probe sampling system. This direct analysis delivers instant results while simultaneously transmitting data to secondary systems, significantly reducing processing delays and enhancing production efficiency.

In this project, we innovatively integrated the sublance model with the four aforementioned systems, sparking novel technological synergies. During the static modeling phase, the incorporation of flue gas analysis and audio-based slag monitoring technologies enables critical functionalities: By integrating acoustic indices, the system alerts operators to slag splashing (drying-back) incidents and automatically adjusts lance positions in automated steelmaking mode. Simultaneously, the flue gas analysis equipment analyzes CO/CO₂ values during blowing, providing optimal flux addition timing guidance. In automated operations, the system automatically adjusts lance positions based on CO/CO₂ trend analysis to preempt slag splashing (drying-back).

Adaptation of the model to flue gas analysis and Audio-Based Slag Formation System

Adaptation of the model to DA rapid analyzer